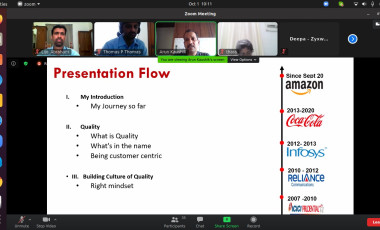

The Quality Journey: Talk by Arun Kaushik of Amazon

It is imperative to look at the quality objectives and business objectives together and not in silos. So that means engaging the teams and functions to reach the organisation objectives by doing x, y, z things. Find the gaps by asking yourself questions.

“Do we have the processes to reduce this cost?”

“Are the original equipment makers selling us the products we already have?”

“What is the redundancy of the existing repair and maintenance?”

“What are my inventory management practices?”

So everything, whether it be manufacturing, logistics, services, we have to link it to the processes. Or it has to be connected to how we will go about them to generate insights from it. Whatever we do in quality functions, whatever way we want to go about it, should relate to the organisational aim.

To sum it up, this is how to build that kind of quality culture in an organisation. Every organisation has to start one day, and they begin with some SOP, some matrix, some management behaviours.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Source: Arun Kaushik’s Presentation

We have to start somewhere, so every organisation begins with minimal expectations while implementing this change management. But as we grow further, we improve on the mid-level capability. It is again organisation maturity in terms of quality culture. We can always bypass some of the intermediate steps. Probably we can go from low capacity to high capability directly as well. But as a natural progression, we move as well to continuous improvement. We always ask ourselves and work on how to upgrade, how better to standardise processes. The quality we can adopt and, of course, the frequency will reflect how we improve performance, rewards linked to these projects, continuation improvements, et cetera.

In every workspace, the market leaders always put the customer first. Everything they do as part of their quality culture is putting the customer first and moving backwards. They evaluate what they need to do to meet this, what resources they need, and what things they need to correct. So it is always the customer first for successful organisations.

Any organisation which is looking for a higher capability in terms of quality should put the customer first. They should look for quality at the source, rather than allowing the defects to get generated at one step and grid locking the entire process.

For an eCommerce company, the whole process starts in the fulfilment centres. Then it goes to sorting centres, from there to delivery stations. So there are multiple nodes that segments flow into. Whatever defects generated in the fulfilment centres can snowball into a multiplication of defects or cascade into subsequent nodes. Thus, for any high-quality capability, we should try to restrict the fault at its source.

Another important point when discussing higher quality capability culture is the cross-functional aspect. Quality can never be in silos. It is not about individual quality function, but together they should be the best, that should be the aim. There should be a process for collaborating across functions, working out what is best for both teams. That is how you could generate the extra edge.

Cross-functional collaboration is one aspect needed for any organisation that is moving to the next stage. Don’t do individual functional projects, but the emphasis should be on cross-functional projects. Continue to do the cross-functional project.

You shouldn’t settle for personal improvement in silos, but you should always link it to the organisational objectives.

Last but not least, never settle for the status quo when you are on a quality journey. Today we might have delivered a saving, or a customer satisfaction score or delivered a turnaround time, improved on SLA, but that’s not enough. Organisations that are leveraging quality cultures will never settle for the status quo. The company could be the best in the market or better than the competition. You might even have everything you are looking for, but you will have to devote more time to make your organisation even better.

Don’t settle for where you are today; look further.

So from a quality perspective, look at what better way to serve the customer. What can you do better for the organisation: If I have ten customers, can I generate 11 out of the ten customers? If my cost to revenue per cent is 10%, can I make it 9%? Can I make it 8%? I am the best in the industry, but still, can I do better? So that is the underlying philosophy for the quality culture of any organisation.

Sponsors of Quality

Sponsors of quality should be influential people who can drive this change. People by nature resist change. How do we address this? We should have the entire organisation, the management and the key people sponsoring these changes be part of the process.

The last piece is that while the management sponsors are important, you matter in the quality deliverable as an individual. While working on an exercise, maybe documentation, try to do it the best way possible, see how fast you can do it. The onus is on every individual in the organisation to make a better version of themselves: whatever they are doing.

Do I have a task cut out for me which I was taking x time one month back? Today am I doing it faster, better and is it an improved version compared to last month’s? Once everyone looks at the organisational objective, they realise work comes with specific responsibilities, a certain period, certain additional bandwidth. So it is everyone’s responsibility to drive the quality culture of their organisation.

(Talk by Arun Kaushik Paraphrased by Nisha Oommen)